STAS, a renown Canadian-based supplier of high-tech process equipment whose mission is to partner with its customers from the aluminium industry to achieve their production goals, has more than 1000 machines installed in more than 35 countries.

In 30 years of history, STAS employees, which are now close to 200, have been working very closely with customers to identify solutions to improve production and the quality of the metal from the potroom to the casthouse.

With the introduction of the new digital economy, companies across the aluminium value chain are revisiting their processes and are re-thinking how they run their operations. For the aluminium industry, more specifically, producers are applying Industry 4.0 ideas and big data insights to improve their operations. From managing production to ensuring the proper quality and delivering products to end customers exactly as expected, producers must now rely on intelligent technologies to optimize their process that leaves no space for mistakes and imperfections.

STAS has adopted a technology agenda that clearly responds to these trends and is positioning itself as a market leader in designing and producing connected, intelligent machines for the aluminium industry.

Our R&D department which consists of 20 experts in process, automation, and engineering has been in the last couple years able to propose new ways to use data to make smart decisions, meet industry regulations while simultaneously allowing customers to save money through automated operations and increased customer satisfaction.

Optimized pot control using STARprobe TM for bath properties measurement

Nevertheless, the aluminum industry is generally a conservative industry, and things take time. The penetration of new technologies and robotization is slow and laborious, yet irreversible – it is even called by many the 4th industrial revolution. Like us, our customers are present in industry forums 4.0. All refer to the terms industry 4.0, big data, smart factory. However, they are at the same time defining their strategy, sometimes waiting for other to take the risks of trying the ‘last big thing’.

Generally speaking, aluminium producers are reluctant to allow direct connectivity of equipment through the internet. Concerns are expressed about the confidentiality of data, of course, but mainly about safety threats from connection to the web. However, these can be effectively addressed, and it is only a matter of time until we see the opening of privileged connection channels.

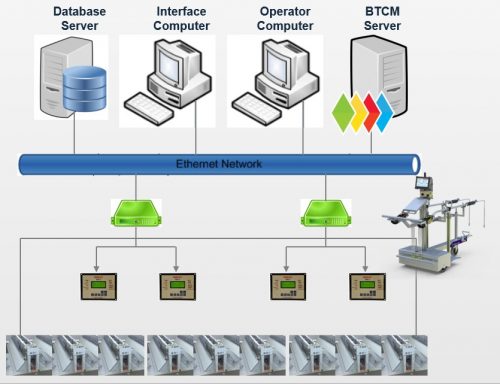

Some of our customers already accept the opening of secured channels with our newest products and allow access to data via secured VPN, such as our ASIS3D (anode stub inspection system) and STAR Probe TM (instant measurement of four bath properties). They can thus get measurable benefits on their operation thru system optimization.

We believe that the trend will be opening in the next few years if two conditions are met: Customers will need to benefit from it measurably (financially but also in the deployment of resources who can focus on task for which the human effort has a clear added value) and if security is assured. The digitalization of smelters and casthouses is already underway and STAS equipment already either all automated or disposed to become automated, using state of the art IIOT applications. Things evolve very fast and stakes are high. Together with our partners and customers, we are proud to prepare the future of the aluminum industry.