How it works

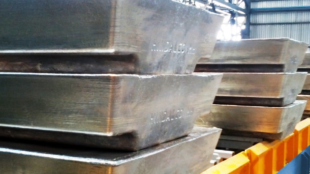

The SCS / Sow Casting and Stacking machine is operated on a continuous or semi continuous basis depending on metal supply capacity and can be tailored to a range of production sizes. The equipment is designed for automatic operation with minimal operator input required.

Molten aluminium is poured from hydraulically-operated crucible tilters directly into the sow moulds. The automatic sow moulds filling system ensures a smooth, accurate pour that results in consistently sized sows.

Two crucible tilters can be installed in parallel to allow for smooth changeover between crucibles, thus allowing for a continuous casting operation.

The sow moulds are supported on individual trolleys that are interlinked to form a continuous chain. After pouring, the metal is skimmed via the robot skimming device which removes any dross. Solidified sow ingots are removed from their moulds via a vacuum demoulding device and transferred to the sow stacking machine. The sows then travel along conveyors where they are weighed, marked and stacked. The completed sow stacks can then be removed via a forklift.

Key features

Metal Quality Improvement

- Suitable for a range of sizes.

- Designed for safe operation and hazard prevention.

- Designed for efficient equipment maintenance.

- Long-lasting, durable components.

- Metal Pouring Arrangement with mould filling control system and robotic skimmer.

- Crucible tilter.

- Forced air cooling system.

- Electric or gas powered mould preheat system.

- Mould spray unit.

- Vacuum demoulding device.

Stacking system also available including:

Sow transfer conveyor.

Sow weighing station.

Sow marking unit.

Sow stacking device.

Stack storage conveyor.

By delivering design excellence, manufacturing quality and effective project management for its extensive product line that now includes casting solutions, the global STAS team is your partner of choice to help achieve your production goals.

Other compatible equipment – Metal treatment and casthouse technologies

Metal treatment and casthouse technologies