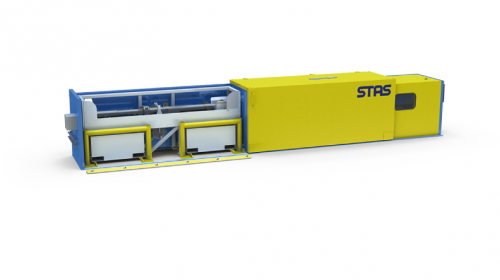

The Proven Technology for Rapid and Efficient Cleaning of Crucibles.

Crucible workshop

Crucibles and siphons used in aluminium smelters must be cleaned and maintained to optimize metal transportation from the potroom to the Casthouse. As an increase in cell amperage leads to higher potroom production and metal transportation, this cleaning step becomes more crucial. Crucible cleaning involves the removal of metal/bath deposits and must be followed by crucible preheating. Siphon and tapping tube cleaning are also very important in the process. STAS designs and manufactures the most reliable, technologically-advanced equipment for this crucial part of the aluminum production process.

An automatic equipment designed to reduce siphon tubes cleaning time, extends the tube life and greatly improves safety.

A safe and efficient system using electrical heaters to preheat metal crucibles and/or dry their refractory linings.

A semi-automatic, pneumatic reamer designed to reduce the siphon cleaning time, extends the tube life and greatly improves safety.

We value your privacy

We use cookies to improve your browsing experience, provide personalized content and analyze our traffic. By clicking on “Accept all”, you consent to the use of cookies. Privacy policy.

Customize your cookie settings

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information on all cookies under each consent category below. Cookies classified as “necessary” are stored on your browser, as they are required to enable basic site functionality. We also use third-party cookies to help us analyze how you use this website and to save your settings. These cookies will only be stored in your browser with your prior consent. You can select the settings of your choice. However, disabling certain cookies may affect your browsing experience.

Necessary

Necessary cookies are required to enable basic functionality of this site, such as providing a secure login or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Obligatoire

Necessary

Necessary cookies are required to enable basic functionality of this site, such as providing a secure login or adjusting your consent preferences. These cookies do not store any personally identifiable data.

| Cookie | Durée | Description |

|---|---|---|

| PHPSESSID | Session | This cookie is native to PHP applications and is used to store and identify a user's unique session in order to manage user sessions on the website. |

| wp-wpml_current_language | Session | This cookie stores the language preference while browsing the site. |

| acceptedCookies | 30 days | This cookie stores preferences related to website cookies. |

Analytic

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on measures such as number of visitors, bounce rate, traffic source, etc.

Analytic

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on measures such as number of visitors, bounce rate, traffic source, etc.

| Cookie | Durée | Description |

|---|---|---|

| _gat | 1 minute | This cookie is installed by Google Universal Analytics to restrain the request rate and thus limit the collection of data on high-traffic sites. |

| _gat_gtag_UA_* | 1 minute | Google Analytics sets this cookie to store a unique user ID. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _ga | 1 year, 1 month et 4 days | The _ga cookie, installed by Google Analytics, calculates visitor, session, campaign data, and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year, 1 month et 4 days | Google Analytics sets this cookie to store and count page views. |