How It Works

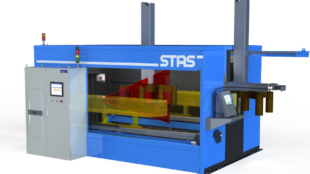

The ASIS3D is a fully automated Anode Stub Inspection System based on the latest 3D technology already in use in other sectors of the industry. It can be adapted to all anode stub sizes and shapes. The system is developed, integrated and manufactured based on state-of-the-art 3D hardware & software designed and supported by world-class suppliers.

The ASIS3D uses a combination of 3D laser sensors installed on a shuttle assembly linked to a linear encoder. The data sets from each sensor are linked to a common triple‑axis coordinate system to build the full 3D model of the stubs. An industrially proven 3D metrology software is then used to automatically perform the measurements.

“Scanning of three-dimensional stub types available with tripods and hexapods configurations.

”

Key Features

The ASIS3D is fully automated, with a design based on robust and proven technologies.

- Can be adapted to all stub sizes and configurations (including hexapods).

- Acquisition of three‑dimensional stub model.

- Measurements are performed to route the anode rods automatically toward the repair loop or to be reused.

- The complete inspection process requires less than 30 seconds.

- Perfect rodding can be ensured by numerically simulating the stub inputs in the anode model.

- Repair stations are optimized and fed with precise and relevant information.

- Custom measurements can be added if required.

- When used with STAS anode rod tracking technology (ART), the condition of the stubs can be related to the performance of the electrolysis cells.

- Anode stub maintenance can be greatly optimized and monitored.